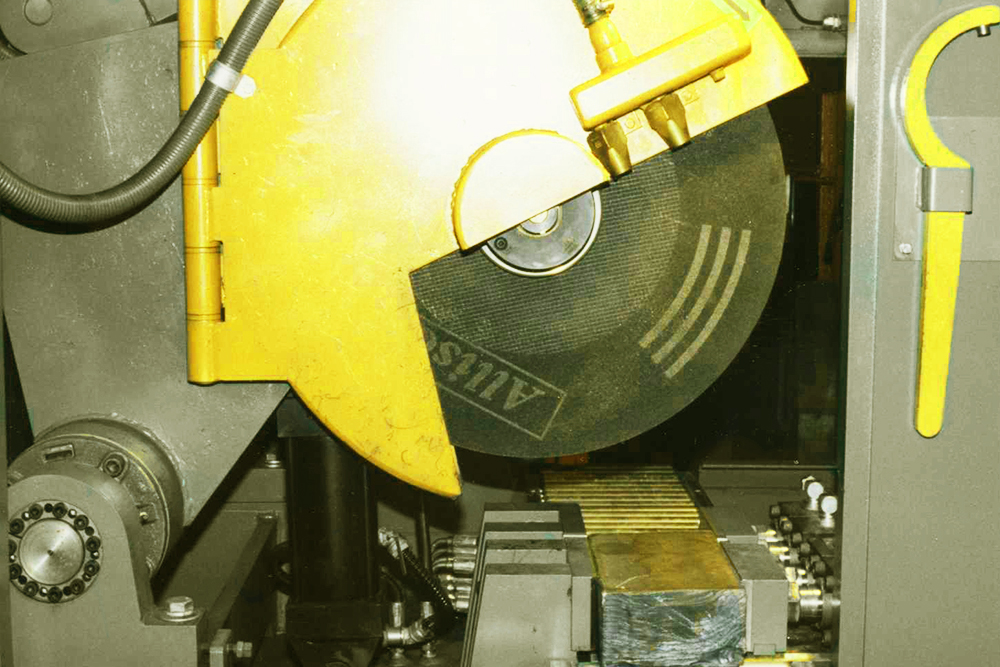

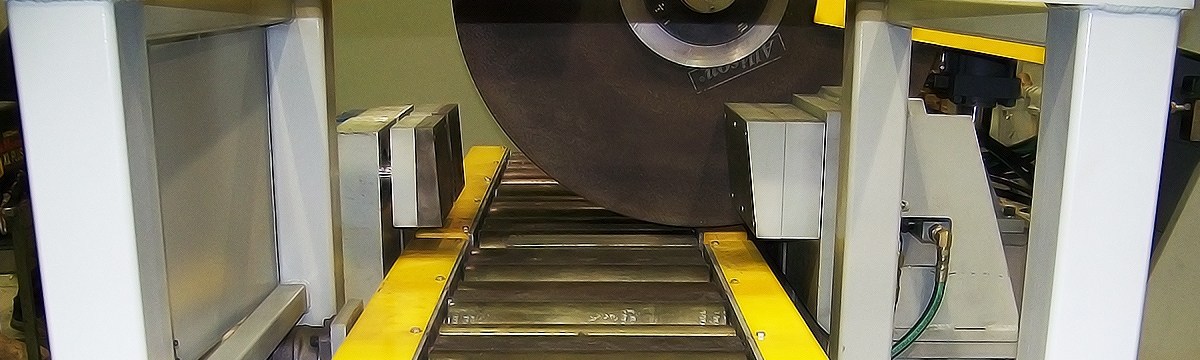

Guillotine Saw

The Guillotine Saw, which is part of the Savage Saw product line, is Thermatool’s solution for companies looking to cut specialty alloys, hardened steel bars or shapes in a high production environment using both dry and wet abrasive cutting techniques. This Series will precision cut up to a 10″ (250mm) diameter billet or 10″ sq (250mm) bar, with the saw cut having a machine like finish with ±.002″ per vertical inch squareness and ±.005 length tolerance, and do all this in less than 100 seconds for a 10″ (250mm) dia piece, which is at least 50 times faster than the best band saw available today. These machine tools are designed with rigidity to ensure the efficient use of high horsepower in cutting the most difficult materials with ease, speed, and precision with low maintenance. Oscillation is available on these models as standard, to improve cut quality, reduce cut time and increase blade life.

The Guillotine Saw has long been the standard for cutting specialty steels; however Thermatool has continued to innovate to improve performance levels. The updated controls with touch screen input are very easy to operate, only requiring the operator to enter material diameter, cut length and to start the cycle allowing for ‘Operator Free’ cutting. Servo controlled Pusher Infeed systems and Magazine Loaders are offered along with several other options such as coolant filtration, part stamping, weighing, and unloading. Whether you are looking for a complete sawing solution with material handling or just a saw to speed up your cutting process let our Savage Saws solve these problems for you.

Features

Standard:

- Cut specialty alloys, hardened steel bars or shapes in a high production environment.

- Used for high production environment using both dry and wet abrasive cutting techniques.

- Precise, automatic clamping ensures product stability during the cut.

- Laser guided cut length.

- Servo blade feed continuously monitoring load developed by the blade motor.

- Variable blade speed to compensate blade wear – maintaining constant surface blade velocity SFPM.

- Equipped with oscillation to improve cut quality, reduce cut time and increase blade life.

Optional:

- Wet/Dry

- Ferrous and non-ferrous Application

- Material handling

- Loading and off-loading table

- Servo driven pusher (material feed) up to 30 feet, part positioning – Length tolerance +/- 0.005”

- Infeed/outfeed conveyor

- Weighing station

- Crop reject unit

- Part segregation

Tech Specs

| Model | SG-110 | SG-130 | SG-150 | SG-175 | SG-1100 |

| Horsepower | 10Hp (7.5Kw) | 30 Hp (22kW) | 50 Hp (37kW) | 75 Hp (56kW) | 100 Hp (75kW) |

| Capacity | 2” Dia (50mm) | 4″ Dia (100mm) | 6″ Dia (150mm) | 8″ Dia (200mm) | 10″ Dia (250mm) |

| Blade Diameter | 14” (300mm) | 24″ (610mm) | 26″ (660mm) | 30″ (7560mm) | 40″ (920mm) |

| Rate of Cut | ½ in2/sec | ½ in2/sec | ½ in2/sec | 1 in2/sec | 1 in2/sec |

| SFPM | 6000-10,000 | 8000-12,000 | 8000-12,000 | 8000-12,000 | 8000-12,000 |

| Variable Speed | Yes | Yes | Yes | Yes | Yes |

| Oscillation | None | Variable | Variable | Variable | Variable |

| Spindle Drive | Kevlar Belt | Kevlar Belt | Kevlar Belt | Kevlar Belt | Kevlar Belt |

| Spindle Feed | Hydraulic/Automatic | Hydraulic/Automatic | Hydraulic/Automatic | Hydraulic/Automatic | Hydraulic/Automatic |

| Clamping | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic |