ScanMaster Induction Scanners

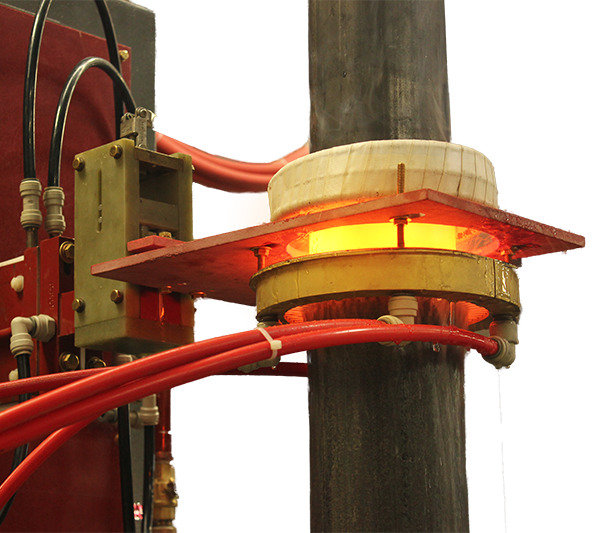

The ScanMaster induction scanner is a high performance induction scanning system able to accommodate heat treating for a wide variety of part weights and lengths. Ideal for mid-to-high volume and/or multi-shift operations, the ScanMaster® scanner’s dual spindle or triple spindle units allow for maximum production flexibility.

Radyne ScanMaster® Induction Scanner Features

A typical ScanMaster® induction scanner includes the ScanMaster® induction scanner, an induction power supply, standard guarding with safety light curtains, ScanMaster® controls and a configurable water/quench cooling system.

ScanMaster® induction scanner components can be incorporated together or separately to meet specific needs, and can be easily adapted for use with external material handling units, such as a pick-and-place, linear transfer, clamp transfer and more.

Our user friendly control system simultaneously controls scan speeds (0-6 in. [152.4 mm] per second), rotation speeds (0-400 rpm), heat levels, heat times, quench times, quench temperature, time delays, and six additional user custom digital outputs.

Radyne Induction Scanner and Pop Ups can handle large and small parts, spanning from under an ounce and shorter than an inch to over 5000 lb. in weight and more than 120 in. in length.

Applications:

Heat Treating, Brazing & Soldering, Shrink Fitting, Heat Staking.

Features

- Dual or Triple Spindles

- Built-in quench tank

- Movable Upper Center Spindle for quick and easy changeovers

- Self-contained system easily integrated into work cell

- Different power ratings and frequency ranges available for application-matched precision hardening

- User-friendly controls simplify set-up, changeover, and diagnostics

- Flexible work piece capacity

- Simple utility connection for fast, low cost installation

- Optional QAS 2000 Monitoring and Alerting System which provides process monitoring and traceability for each part processed

Tech Specs

| ScanMaster® 28 | ScanMaster® 44 | ScanMaster® 63 | ScanMaster® 120 | |

| Scan Length | 28 in. [71 cm] | 44 in. [111 cm] | 63 in. [160 cm] | 120 in. [304 cm] |

| Spindles | Dual Spindles | Triple Spindles | Dual or Triple Spindle | Single Spindle (3-Jaw Chuck) |

| Spindle Spacing | 8 in. [203 mm] | 6 in. [152 mm] | 6 in. [152 mm] | — |

| Rotation Speed | 0-400 RPM | 0-175 RPM | 0-175 RPM | 0-60 RPM |

| Part Weight | 75 lb. per spindle | 500 lb. per spindle | 500 lb. per spindle | 5000 lb. |

| Single Part Diameter | 18 in. [457 mm] | 20 in. [508 mm] | 20 in. [508 mm] | 30 in. [762 mm] |

| Dual Part Diameter | 6 in. [152 mm] | 8 in. [203 mm] | 8 in. [203 mm] | — |

| Dimensions | 77W x 38D x 91H in. [195W x 97D x 231H cm](121H in. [307 cm] Fully Raised) |

77W x 38D x 116H in. [195W x 97D x 294H cm] (150H in. [391 cm] Fully Raised) |

82W x 76D x 143H in. [208W x 193D x 363H cm] (170H in. [431 cm] Fully Raised) |

186W x 104D x 180H in. [472W x 264D x 457H cm] (210H in. [533 cm] Fully Raised) |

| Operator Interface | Touchscreen Controls Package | Touchscreen Controls Package | Touchscreen Controls Package | Touchscreen Controls Package |

| Quench Tank | 200 gal./50 GPM [757 L/189 LPM] 300 gal./100 GPM [1135 L/378 LPM] |

200 gal./50 GPM [757 L/189 LPM] 300 gal./100 GPM [1135 L/378 LPM] |

200 gal./50 GPM [757 L/189 LPM] 300 gal./100 GPM [1135 L/378 LPM] |

1600 gal./400 GPM [6056 L/1514 LPM] |

| Quench @ 50% Duty Cycle | — | 200 kW/400 kW | 200 kW/400 kW | 600 kW |

Accessories

- Quick Disconnect – Quick change tooling for coil mounting

- Robotics and Material Handling Integration, i.e. integrated bowl feeders, rotary tables, step feeders, conveyors, or 6 axis robotic arm

- QAS 2000 Quality Assurance System

- Pyrometer Sensor

- Chillers

- Automatic/Semi-automatic part handling modules